A bottle top dispenser is a fundamental laboratory instrument utilized for accurately and safely dispensing precise volumes of chemicals, reagents, solvents, and oils from containers. It serves as a crucial tool in preventing spills, measurement inaccuracies, and potential lab accidents during manual dispensing processes. This apparatus enables controlled delivery of a predetermined liquid volume, typically ranging from 1 ml to 100 ml, directly from a source bottle to a receiving container.

The Accumax Bottle Top Dispenser (BTD) features a unique springless valve design for outstanding chemical resistance and longevity, requiring minimal maintenance.

Components of a Bottle Top Dispenser

1. Piston Mechanism

It typically consists of a piston, a seal, and a spring. when you turn the adjustment knob, it moves a piston inside the dispenser barrel. This piston motion creates either a vacuum or pressure inside the barrel. When you press down on the piston, the vacuum or pressure then helps draw liquid into the dispenser or push it out, depending on which way you’re turning the knob.

2. Adjustment Knob

It lets you choose how much liquid you want to dispense. By turning a knob, you control a piston inside the dispenser that determines the volume of liquid released. This ensures you can dispense liquids accurately and precisely for your experiments.

3. Dispensing Nozzle

It controls the flow of liquid, allowing precise dispensing and measurement. Its valve mechanism ensures uniform dispersion, and compatibility with different bottles, and prevents leaks, making it essential for accurate laboratory work.

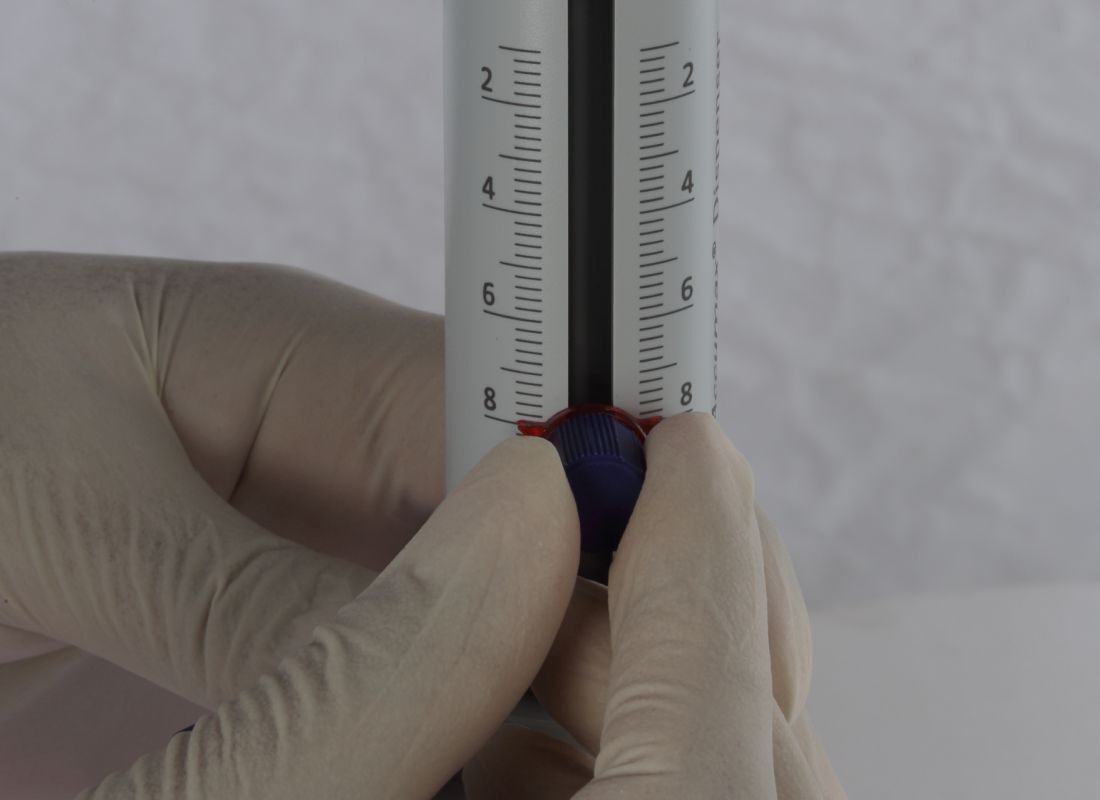

4. Bottle Adapters

They enable bottle-top dispensers to securely attach to different sizes of reagent bottles. They act as connectors between the dispenser and the bottle, ensuring a tight and leak-proof fit. Accumax Bottle Top Dispensers come with a set of four adapters in sizes of 28 mm, 38 mm, 40 mm, and 45 mm.

These adapters allow the dispenser to be compatible with a wide range of laboratory reagent bottles, regardless of their neck sizes

Types of Bottle Top Dispensers

Fixed Volume Dispensers

They are designed to dispense a specific, pre-set volume of liquid with each operation. These dispensers are ideal for applications where the same volume of liquid needs to be dispensed repeatedly and accurately. They typically do not have an adjustment knob and are calibrated to dispense a single fixed volume.

Adjustable Volume Dispenser

They allow you to manually set and adjust the volume to be dispensed using a knob or dial mechanism. This flexibility makes it suitable for a wide range of experiments and analytical tasks, ensuring accuracy and efficiency in liquid handling. These dispensers are versatile and suitable for applications where different volumes of liquid need to be dispensed accurately.

Advantages of Using a Bottle Top Dispenser

- Ergonomic design: They are designed to ensure comfortable handling during operation, reducing hand fatigue and improving user experience.

- Versatility: They can accommodate a wide range of liquids, including acids, bases, and organic solvents, making them suitable for various laboratory applications.

- Time-saving: Bottle top dispensers streamline the liquid dispensing process, saving time and effort compared to manual pipetting or other methods.

- Compatibility: They often come with adapters to fit various sizes of reagent bottles, increasing their versatility and compatibility with different laboratory equipment.

Optimizing Use and Maintenance of Bottle Top Dispenser

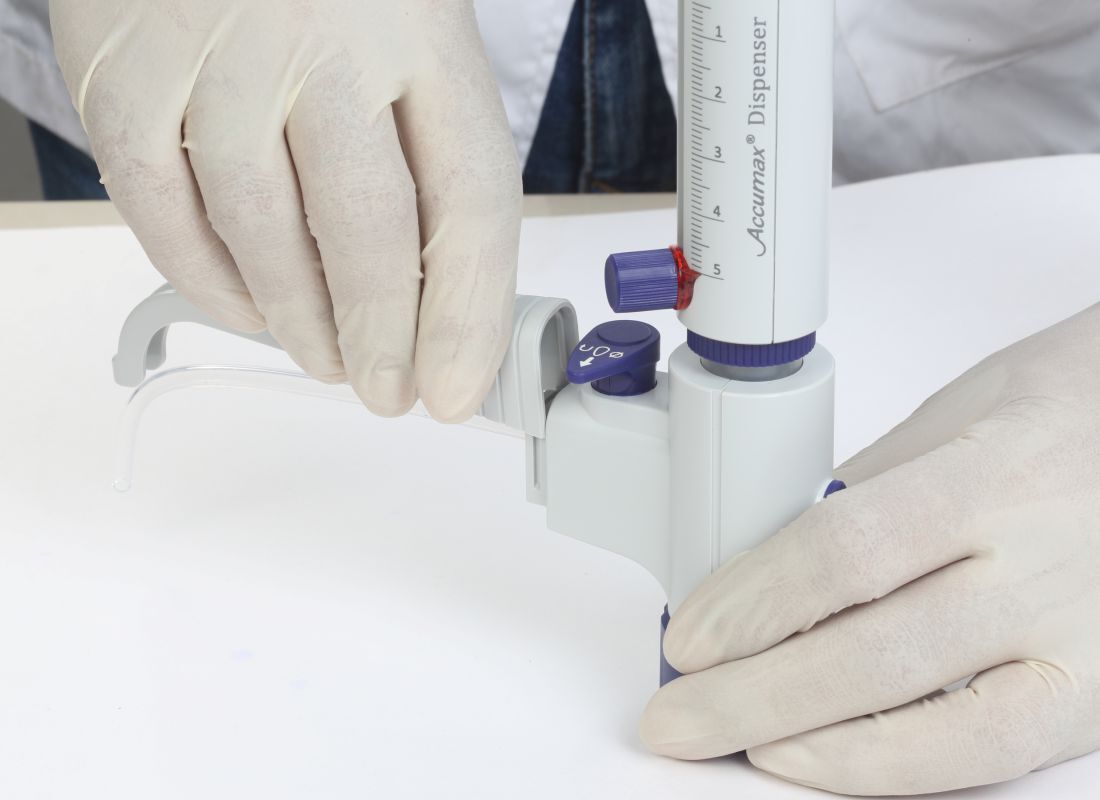

Preparing the dispenser

- Before you begin, ensure the dispenser is clean and free from any residue or contaminants.

- Operate BTD several times with the dispensing nozzle submerged in the same solvent or buffer that will be dispensed. This action removes any air bubbles and guarantees precise dispensing. This process, known as priming, is crucial as it minimizes residue buildup up to the tip when using the same solution. Additionally, locking in the volume setting further prevents any accidental leakage, ensuring smooth and accurate dispensing.

Click here for a detailed video guide for the correct way use a bottle top dispenser

Dispensing techniques for accurate results

- Always hold the dispenser vertically when dispensing liquid to ensure accurate volume delivery.

- Depress the dispensing lever smoothly and steadily to avoid splashing or dripping, which could lead to inaccurate results.

- After dispensing, allow a few seconds for any residual liquid to drain from the dispensing nozzle to prevent over-dispensing.

Cleaning and sterilization

- Regularly clean the dispenser after each use to prevent contamination and maintain accuracy. Use a mild detergent solution followed by rinsing with distilled water.

- For sterilization, autoclave the dispenser components according to manufacturer’s guidelines, especially if used with biological samples or in sterile applications.

Calibration and Recalibration of Bottle Top Dispenser

- Follow the manufacturer’s instructions for the initial calibration of the dispenser to ensure accurate volume delivery.

- Regularly recalibrate the dispenser according to the recommended schedule or if there are any signs of inaccuracy. This may involve adjusting the piston mechanism or verifying the volume delivery using a calibrated reference instrument.

By following these, you can ensure that your bottle-top dispenser performs optimally, provides accurate results, and has a longer lifespan, contributing to the overall efficiency and reliability of your laboratory operations.

Common Mistakes to Avoid While Using Bottle Top Dispenser

A. Overfilling or underfilling the dispenser:

- Overfilling can lead to spills, inaccurate measurements, and potential contamination of the dispenser.

- Underfilling may result in air bubbles entering the system, affecting dispensing accuracy and precision. It’s crucial to adhere to the recommended filling volume specified by the manufacturer.

B. Incorrect calibration:

- This can lead to inaccurate volume delivery, compromising the reliability of experimental results.

- Ensure the dispenser is calibrated according to the manufacturer’s instructions or recalibrated if there are signs of inaccuracy.

C. Using the wrong type of dispenser for the liquid:

- Choose a dispenser that is suitable for the chemical properties and viscosity of the liquid being used to ensure proper functionality and accuracy. This can prevent corrosion, damage to the dispenser, or inaccurate results.

D. Neglecting maintenance routines:

- Failing to clean and maintain the dispenser regularly can lead to contamination, buildup of residues, and deterioration of performance over time.

- Follow the recommended maintenance procedures provided by the manufacturer to ensure the dispenser operates optimally and maintains accuracy.

Looking for the best Bottle Top Dispensers?

Accumax stands out as a leading manufacturer of liquid handling equipment, lab consumables, and benchtop instruments. Accumax Bottle Top Dispenser (BTD) epitomizes excellence in design and functionality in the realm of lab devices.

Crafted meticulously from top-quality materials, this innovative dispenser guarantees precision and unmatched durability, ensuring reliable performance for years to come. Accumax’s commitment to sophistication and functionality makes their bottle top dispenser an indispensable tool for laboratories seeking unparalleled quality and longevity in liquid handling equipment.